Hot Induction Bend

Request for Quotation? Feel free to Chat with Us

Descriptions

Hot Induction Bending is formed by passing pipe through an induction bending machine. This machine uses an induction coil to heat a narrow band of the pipe material. As the pipe is pushed through the machine, a bend with the desired radius of curvature is produced. The heated material just beyond the induction coil is quenched with a water spray on the outside surface of the pipe. Thermal expansion of the narrowly heated section of pipe is restrained due to the unheated pipe on either side, which causes diameter shrinkage upon cooling.

The induction bending process also causes wall thinning on the extrados and thickening on the intrados. The severity of thinning/thickening is dependent upon the bending temperature, the speed at which the pipe is pushed through the induction coil, the placement of the induction coil relative to the pipe (closer to the intrados or extrados), and many other factors.

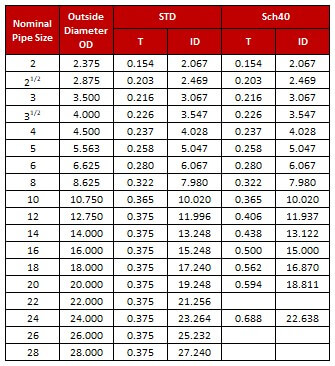

Our Production Range

STD, Sch40, X-S, Sch80, Sch160, XX-S

Asme B16.9 / PFI STD ES-24

Sch20, Sch60, Sch100, Sch120, Sch140

Asme B16.9 / PFI STD ES-24

STD, Sch40, X-S, Sch80, Sch160, XX-S

Asme B16.9 / PFI STD ES-24